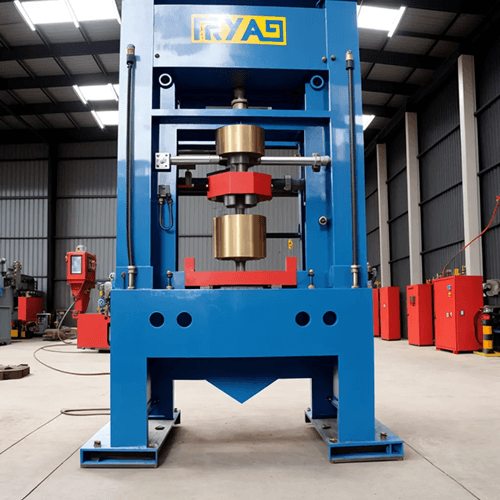

Hydraulic deep drawing press machines are indispensable in various industries for their ability to shape metal sheets into complex components. These machines operate under high pressure and are crucial to maintaining efficient production processes. To ensure the longevity and optimal performance of your hydraulic deep drawing press machine, proper maintenance is key.

In this post, we’ll discuss 5 essential hacks for maintaining your hydraulic deep drawing press machine.

Regular Inspection

Routine inspections are fundamental to keeping your hydraulic deep drawing press machine in top condition. Inspect the machine for any signs of wear and tear, leaks, loose bolts, or damaged hydraulic hoses. Pay close attention to critical components such as the hydraulic pump, cylinders, valves, and seals. Identifying and addressing issues early can prevent costly breakdowns and production downtime.

Lubrication

Proper lubrication is crucial for the smooth operation of a hydraulic press machine. Regularly check and lubricate all moving parts to reduce friction and wear. Use the recommended lubricants and follow the manufacturer’s guidelines for lubrication intervals. This simple maintenance task can significantly extend the lifespan of your machine.

Hydraulic Fluid Maintenance

Maintaining the hydraulic fluid is vital to ensure the machine’s performance and longevity. Regularly check the hydraulic fluid level and quality. Over time, hydraulic fluid can become contaminated with debris and moisture, which can damage the system. Change the hydraulic fluid at the recommended intervals and use high-quality hydraulic oil suitable for your machine.

Pressure Adjustment

Maintaining the correct hydraulic pressure is essential for the deep drawing process. Periodically check the pressure settings and calibrate the machine as needed. Incorrect pressure settings can lead to poor-quality products and potential damage to the machine. Consult the machine’s manual or an expert technician to ensure accurate pressure adjustments.

Operator Training

Properly trained operators are a crucial aspect of hydraulic press machine maintenance. Ensure that your operators are well-trained in operating the machine safely and efficiently. They should be familiar with the machine’s controls, safety protocols, and routine maintenance tasks. Regular training and refresher courses can help prevent accidents and ensure that the machine is used correctly.

You can now look for more info about these machines in the linked website and also enjoy the affordability of these machines.