Selecting the perfect photopolymer plate makers for the kind of tasks you want to accomplish is not an easy thing. It even gets harder when you are a newbie. However, what most people do not realize is that you can easily buy the best photopolymer plate maker in the market, even for the first time.

For newbie buyers, this guide will help you get the best plat maker in the market. Check out the following 5 tips:

Size Matters

Start with getting the size of the photopolymer plate maker correct. The best way to go about it is to understand the kind of tasks that you want to do, and this will help you get the best quality machine. You might also need to get advice from professionals. Therefore, you need to get the issue of size correct.

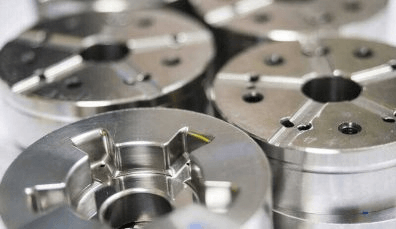

Quality Machine

The overall quality of the machine must be outstanding. Do not compromise on this because it will greatly affect your value for money. There are a number of ways that you can determine the quality of the machine, but the best way is to check the quality of the materials. Every part must be made from the best grade of the material available.

Cutting Edge Tech

The photopolymer plate maker uses a range of technologies, including engraving technology. For the first-time buyer, the trick must be investing in cutting-edge technology. Make sure that you don’t end up with an obsolete machine.

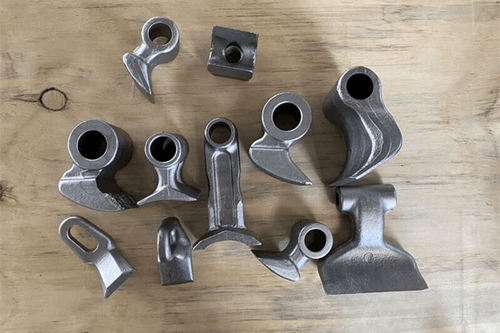

Versatility

The other important buying tip for the photopolymer plate maker is the machine’s versatility. You must ensure that you are investing in the most versatile machine for the kind of plates you are making. This will save you a lot of money.

Machine Cost

The best photopolymer plate maker is one that is affordable and also offers the best quality in the market. The price of the machine might be better than the market rate and also offer investors excellent value for money. Therefore, check the cost of the machine.

For some of the best photopolymer plate makers in the market today, go here. The company will get you sorted at an affordable price.